Intellectual Property

|

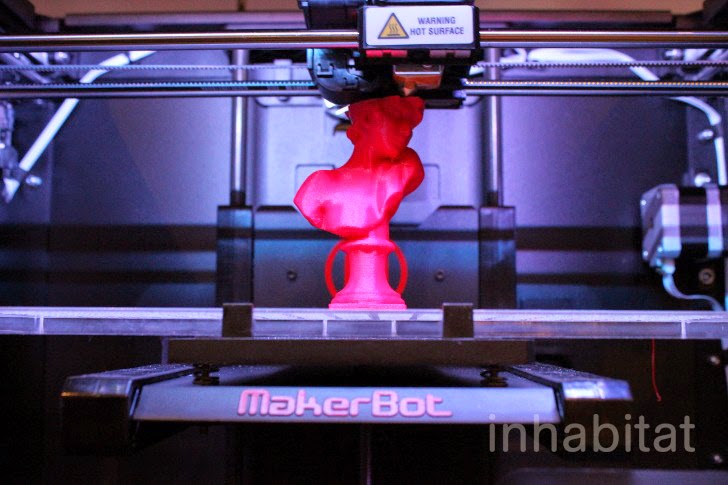

Consumer Grade 3D Printer

Image by: Creative Tools via Flickr

|

|

Commercially Available 3D Scanner

Image by: Creative Tools via Flickr

|

New filesharing platforms such as Thingiverse, or My Mini Factory give users the power to share creations and download other peoples designs. This ability is extremely useful to help spread, and create innovative ideas. The downside of such power is creative licensing. Most CAD file sharing websites are self governing and have their own terms and policies on what can be downloaded and what can be shared. While this works well in theory, we have seen this issues in online distribution of other digital media types such as music, or videos. Like music and video, CAD files are very susceptible to illegal downloads.

Another concern shared by many is the use of 3D scanners, which make it possible to scan a physical object to create a CAD file that can then be 3D printed. Currently the performance limitations of 3D printers make it so that it is not possible, or not economically viable to recreate most consumer products. Although right now these limitations keep 3D printers from reaching their full potential, it is likely that 3d printing technology will soon reach extreme heights of manufacturing capability to produce a wide range of goods.

|

| Image by: Inhabitat Blog via Flickr |

Public Safety

Another threat to public safety worth mentioning is product design. Most industries in America that produce consumer products have to adhere to strict standards regarding product safety. If a company sells a faulty product that injuries a consumer, or causes property damage that company can then become responsible for these consequences. Compared to a system of file sharing, There is no system of responsibility for product failures. Proposed regulations to control or limit the distribution of designs for safety purposes will likely trigger many questions of 1st amendment rights infringement.

The Future of 3D printing

3D printers are likely to have an enormous impact society, most of which will be very positive. It is imperative that the necessary due diligence done to explore ethical dilemmas and protect the public.